Strengthen Your Procurement Strategy with Category Management and Supplier Prequalification

In procurement, structure is everything. Without it, organizations risk overspending, inefficient sourcing, and working with the wrong suppliers. One of the most effective ways to bring structure and strategy to procurement is through Category Management—and when combined with Supplier Prequalification, it becomes a powerful engine for cost control, compliance, and

In procurement, structure is everything. Without it, organizations risk overspending, inefficient sourcing, and working with the wrong suppliers. One of the most effective ways to bring structure and strategy to procurement is through Category Management—and when combined with Supplier Prequalification, it becomes a powerful engine for cost control, compliance, and supply chain resilience.

What is Category Management?

Category Management is a procurement strategy that organizes spend into distinct categories—such as office supplies, construction services, ICT, or travel—based on similar characteristics or supplier markets. This allows procurement teams to:

- Focus on the unique dynamics of each category

- Build targeted sourcing strategies

- Strengthen supplier relationships

- Make informed and strategic purchasing decisions

By grouping spend and applying a tailored approach to each category, organizations can drive significant value through better pricing, improved quality, and reduced risk.

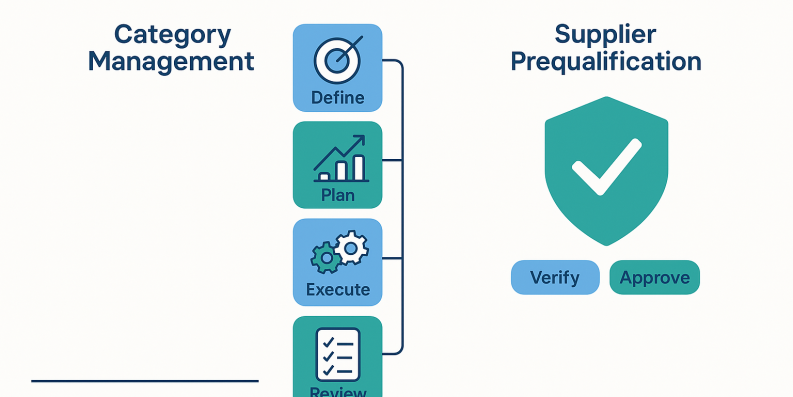

The Process of Category Management

A successful Category Management strategy typically follows this structured approach:

- Determine the Category – Group products/services with shared characteristics.

- Evaluate the Role of the Category – Assess its importance and impact on the business.

- Check the Performance of the Category – Analyze current supplier performance and spend data.

- Set Objectives – Define goals such as cost savings, local supplier engagement, or innovation.

- Develop Strategies – Build sourcing strategies specific to each category’s needs.

- Adopt Tactics – Implement sourcing methods, contracts, or supplier programs.

- Implementation – Execute the strategy, supported by the right tools and people.

- Conduct Category Review – Evaluate performance, risks, and supplier value over time.

This structured, insight-driven process leads to better decision-making, supplier alignment, and operational efficiency.

Where Supplier Prequalification Comes In

While Category Management focuses on strategy and structure, Supplier Prequalification ensures that only capable, compliant, and relevant suppliers are part of that strategy from the start.

Supplier Prequalification is the process of collecting, assessing, and verifying supplier information before they are allowed to participate in procurement opportunities. It evaluates:

- Legal and regulatory compliance

- Financial stability

- Capacity and experience

- Ownership groups (e.g., women, youth, PWD-owned businesses)

- Alignment to specific categories

By integrating prequalification into Category Management, organizations can:

- Build a pool of vetted suppliers for each spend category

- Shorten sourcing timelines

- Reduce procurement and operational risk

- Strengthen compliance with both internal policies and external regulations

- Promote inclusivity and supplier diversity within categories

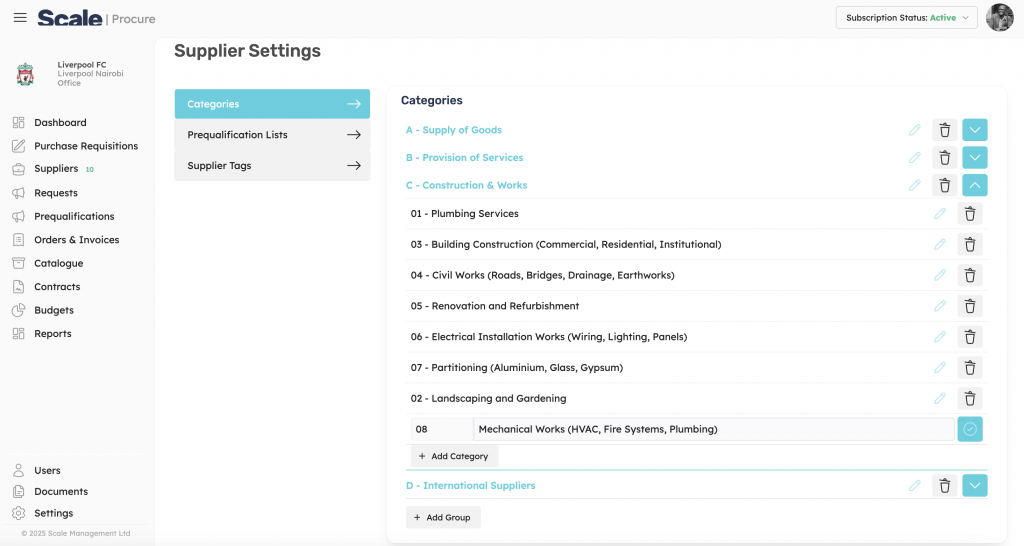

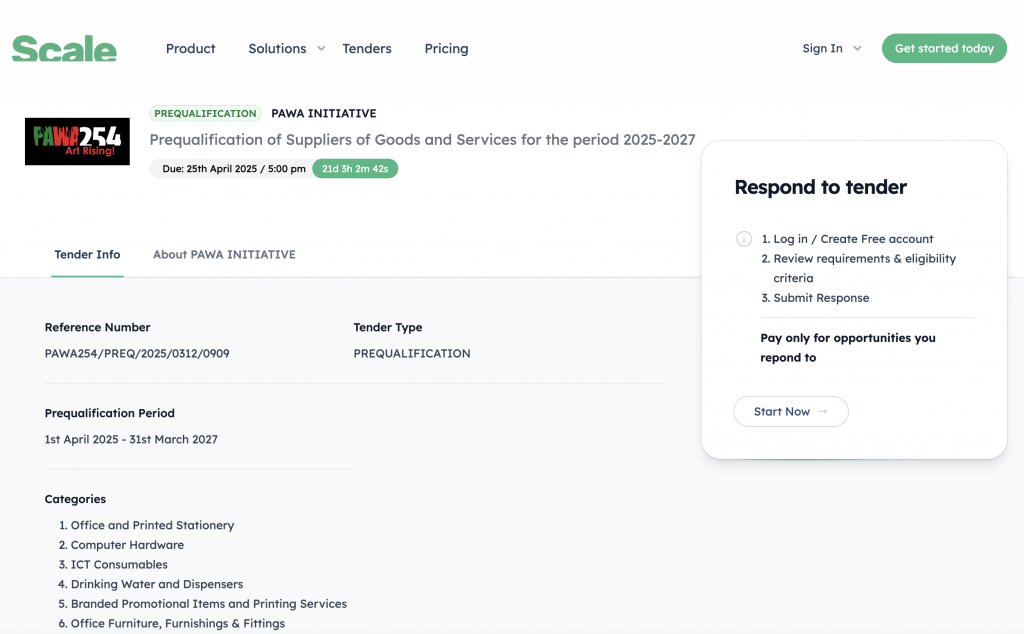

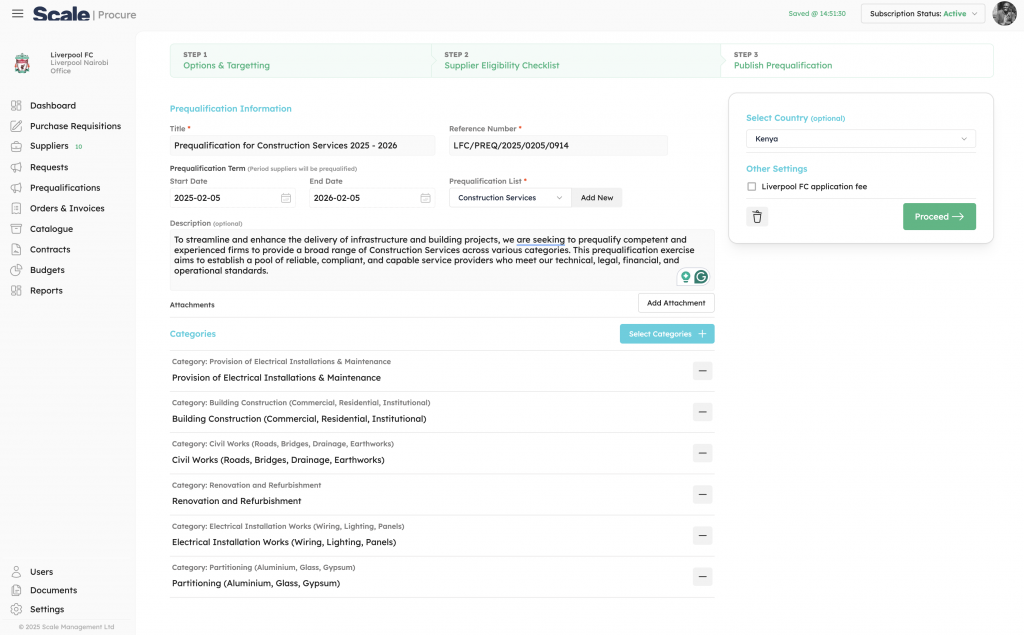

Category-Specific Prequalification with Scale

At Scale, we make it easy to manage both category strategies and supplier prequalification in one platform. Our solution allows procurement teams to:

- Publish prequalification calls by category

- Configure eligibility rules specific to each category

- Evaluate and score supplier submissions

- Onboard approved suppliers into a centralized category-based database

- Track supplier performance over time

For example, if you’re managing a “Construction Services” category, you can create a tailored prequalification process that evaluates suppliers based on construction licenses, safety compliance, and relevant past projects. This ensures that only high-quality vendors are considered during tendering and contracting.

Benefits of Integrating Prequalification with Category Management

- Deeper category insights with verified supplier data

- Faster decision-making with prequalified suppliers always ready

- Stronger negotiation power from supplier benchmarking

- Better alignment between procurement strategy and operational execution

- Compliance made easy with structured evaluation and reporting

Category Management provides the strategic lens; Supplier Prequalification provides the quality control. When combined, they ensure that procurement is not just reactive and transactional but proactive, intelligent, and value-driven.

At Scale, we help organizations across Africa implement these practices through a seamless digital experience that reduces friction and accelerates results.

Want to get started?

Join Scale or Book a Demo to learn how to transform your procurement with Category Management and Supplier Prequalification.