Negotiating Like a Pro: Data-Driven Procurement Strategies for Better Deals

The Negotiation Line You’re on a call with a supplier quoting $60 per unit when $50 is the market norm. Sound familiar? Procurement pros face this daily—construction budgets bloated by inflated material costs, logistics margins squeezed by rising freight rates. The best don’t guess or haggle—they rely on data-driven procurement

The Negotiation Line

You’re on a call with a supplier quoting $60 per unit when $50 is the market norm. Sound familiar? Procurement pros face this daily—construction budgets bloated by inflated material costs, logistics margins squeezed by rising freight rates. The best don’t guess or haggle—they rely on data-driven procurement strategies to negotiate smarter.. This isn’t about one-off wins; it’s about practical, repeatable steps for better deals. Here’s how to master data-driven procurement, day after day.

The Procurement Edge: Data Over Guesswork

No data means blind spots. You might miss a 10% overcharge on steel because of unchecked past spends or overlook late deliveries without stats. Data is your procurement mise—the groundwork that sharpens every negotiation. It’s not optional; it’s your advantage. Top procurement pros don’t wing it—they use proven data-driven procurement strategies. Here are five key tactics to mix into your workday:

Daily Plays: Data-Driven Negotiation Tactics

Top procurement pros don’t wing it—they use proven tactics. Here’s five to mix into your workday:

Spend Scrub

Before diving into negotiations, review the last 6–12 months of purchase data from your ERP or records. Look for discrepancies—like paying 500per ton when the market rate is 450. Armed with this insight, you can confidently challenge the supplier: “Your current price is above market—adjust it to $460.” This quick play delivers an 8% reduction, stacking up wins for your bottom line. A quick 15-minute review at the start of your day can uncover these opportunities.

Performance Push

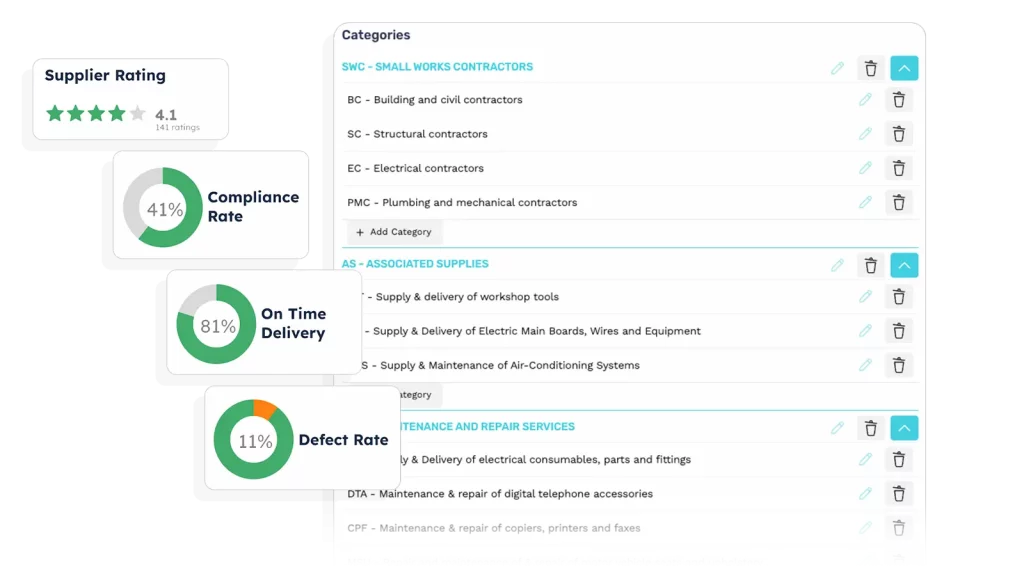

Supplier performance metrics are a goldmine for negotiation leverage. Track key indicators like on-time delivery rates—if a supplier is at 80% while competitors hit 90%, use that data to demand better terms: “You’re underperforming—either reduce costs by 5% or improve delivery times.”

Market Match

Ensure supplier quotes align with industry benchmarks by thoroughly preparing before negotiations. Research market trends, supplier capabilities, and pricing structures to craft well-informed proposals. For instance, if a shipment is priced at $220 while the market average is $200, you can confidently push back: “The standard rate is $200—match it, or we’ll need to explore alternatives.”

Preparation empowers you to anticipate challenges and make data-driven decisions, anchoring every deal in solid market research. For more tips on preparation and avoiding common negotiation mistakes, check out this guide on procurement negotiation strategies.

Volume Leverage

If your order volumes are substantial, use them to negotiate discounts. Review annual purchase quantities—say, 10,000 units—and cross-reference supplier discount thresholds. Present the case clearly: “At this volume, we expect a 10% discount—make it happen.” Lock in bigger discounts by mastering your volume data.

Terms Tweak

Payment and delivery terms are often flexible, but you need data to prove it. Analyze cash flow needs and supplier patterns—if competitors offer 45-day terms while yours insists on 30, push for alignment: “Extend our terms to 45 days—we know you can accommodate this.” This unlocks critical advantages: extended terms boost liquidity, freeing cash for urgent priorities or investments, while faster delivery schedules shrink inventory gaps, ensuring operations hum smoothly.

These strategies aren’t theoretical—they’re practical moves used daily by procurement experts. Tools like Scale can streamline data collection, but the real payoff comes from applying insights consistently.

Building Long-Term Procurement Habits

Beyond tactical negotiations, top professionals cultivate habits that sustain their edge.

- Daily Data Scan – Spend 10 minutes each morning reviewing spend trends or market shifts. Knowing steel prices dropped 3% this week arms you with leverage before talks even begin.

- Supplier Performance Tracking – Midday, assess a vendor’s recent performance—cost, timeliness, reliability. A quick note like “Two late shipments this month” keeps them accountable.

- Backup Supplier Testing – Weekly, place a small trial order (e.g., 100 units) with an alternate vendor. If negotiations fail, you’re not left scrambling.

- Market Rate Updates – Monthly, refresh benchmark rates from trade sources or peers. Cement at 80/ton instead of 85? Use that intel in your next discussion.

- Terms Audit – Quarterly, review payment terms across suppliers. If some offer 30 days while competitors provide 60, push for parity: “Your rival accommodates 60 days—match it.”

Own the Deal

Suppliers may set the starting line, but you hold the reins to shape the final deal. Procurement thrives on your ability to forge advantageous outcomes, not just respond to offers. Take charge with deliberate steps: dissect your spending patterns, arm yourself with data-driven procurement strategies, calibrate prices to market standards, capitalize on volume for discounts, and fine-tune contract terms. Blend these actions into your daily rhythm, and negotiation becomes your steady strength. The next time you connect with a supplier, you’re not merely talking terms—you’re locking in the optimal result.