Beyond the Price Tag: Understanding Total Cost of Ownership (TCO) in Procurement

In procurement, the lowest price often hides the highest cost. What appears “affordable” upfront may become a long-term liability through poor service, high operating costs, or frequent breakdowns. This is why savvy procurement teams rely on Total Cost of Ownership (TCO) — a decision-making framework that considers all costs over

In procurement, the lowest price often hides the highest cost. What appears “affordable” upfront may become a long-term liability through poor service, high operating costs, or frequent breakdowns. This is why savvy procurement teams rely on Total Cost of Ownership (TCO) — a decision-making framework that considers all costs over the lifecycle of a product or service.

At Scale, we help organizations adopt TCO thinking by embedding it into every stage of the sourcing, evaluation, and supplier management process.

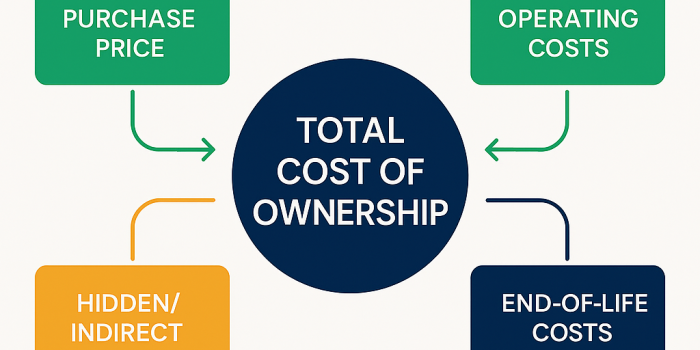

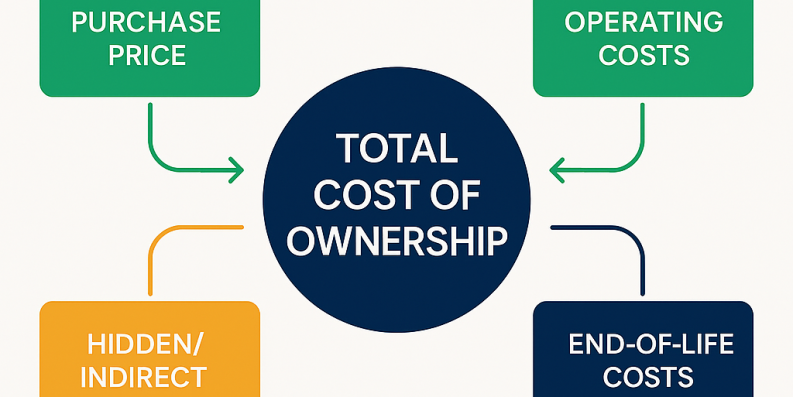

What is Total Cost of Ownership (TCO)?

TCO is the complete cost of acquiring, operating, maintaining, and retiring a product or service — not just the sticker price.

TCO = Purchase Price + Operating Costs + Hidden/Indirect Costs + End-of-Life Costs

TCO Covers:

- Acquisition Costs: Purchase, delivery, setup, training

- Operating Costs: Usage, maintenance, support, licensing

- Hidden Costs: Downtime, inefficiencies, lack of support

- End-of-Life Costs: Decommissioning, replacement, disposal

Why TCO Matters in Procurement

1. It prevents costly surprises

What looks cheap upfront can explode in cost due to poor maintenance, inefficient operation, or expensive downtime.

2. It supports strategic sourcing

TCO enables better decision-making by prioritizing value, not just price.

3. It improves budgeting accuracy

Forecasting long-term costs reduces unexpected budget overruns.

4. It enhances supplier selection

TCO reveals which suppliers will cost less over time — not just today.

5. It promotes sustainability

Durable, efficient, and reliable products often have lower total costs.

Example 1: Buying Hardware (Laptops)

| Criteria | Supplier A | Supplier B |

|---|---|---|

| Unit Price | KES 65,000 | KES 80,000 |

| Warranty | 1 year | 3 years |

| Battery Life | 4 hours | 10 hours |

| Downtime Costs (4 years) | KES 60,000 | KES 8,000 |

| Replacement Cycle | 2 years | 4 years |

TCO over 4 years:

- Supplier A = KES 65,000 x 2 + KES 60,000 = KES 190,000

- Supplier B = KES 80,000 + KES 8,000 = KES 88,000

Insight: The more expensive product is actually the better deal.

Example 2: Procuring Software (e.g., a Platform Like Scale)

You’re evaluating three procurement software solutions. All have different pricing models:

| Criteria | Vendor A | Vendor B | Scale |

|---|---|---|---|

| Annual Subscription | $7,000 | $3,000 | $10,000 |

| User Training | $2,000 | $1,000 | Included |

| Integration | $5,000 | $10,000 | Included |

| Support & Uptime SLA | 90% | 85% | 99.9% |

| Downtime Cost (per year) | $5,000 | $12,000 | $500 |

| Hidden Fees (Add-ons) | $3,000 | $5,000 | None |

4-Year TCO:

- Vendor A = ($7,000 x 4) + $2,000 + $5,000 + ($5,000 x 4) + $3,000 = $55,000

- Vendor B = ($3,000 x 4) + $1,000 + $10,000 + ($12,000 x 4) + $5,000 = $84,000

- Scale = ($10,000 x 4) + $0 (no training/integration/downtime/add-ons) = $40,000

Insight: Scale, though premium-priced, delivers better value and reliability — with the lowest TCO over time.

TCO Checklist for Procurement Teams

Before selecting a supplier or solution, consider the following:

A. Acquisition Costs

Purchase price

Delivery/logistics

Installation or configuration

Training/setup fees

B. Operating Costs

Licensing or subscriptions

Maintenance and repairs

Energy or fuel

Staff time or downtime

C. Hidden or Indirect Costs

Supplier support responsiveness

Compatibility issues

Productivity losses

Cost of inefficiencies

D. End-of-Life Costs

Disposal or decommissioning

Replacement costs

Data migration or cleanup

Sectors Where TCO is Especially Important

Total Cost of Ownership (TCO) is especially important in sectors where the initial purchase cost is only a small fraction of the total lifecycle cost or where operational reliability, compliance, and maintenance are critical. Here are the sectors where TCO has the most impact:

1. Manufacturing & Industrial

- Why it matters: Machinery, production lines, and plant equipment are expensive to maintain, power, and repair. Downtime = lost revenue.

- TCO focus: Energy efficiency, spare parts availability, uptime, service contracts.

2. ICT & Technology Procurement

- Why it matters: Laptops, servers, and enterprise software often come with licensing, training, and support costs far beyond the purchase price.

- TCO focus: Support contracts, updates, user training, cybersecurity risk, and obsolescence.

3. Construction & Infrastructure

- Why it matters: Heavy equipment, building materials, and infrastructure projects have long timelines and usage cycles.

- TCO focus: Maintenance, durability, long-term warranties, cost of rework or early failure.

4. Energy & Utilities

- Why it matters: Power systems, pipelines, and solar installations have high upfront and operating costs.

- TCO focus: Fuel efficiency, servicing, environmental compliance, grid integration.

5. Transport & Logistics

- Why it matters: Fleets of vehicles or transport equipment require regular maintenance and can become a liability if poorly chosen.

- TCO focus: Fuel consumption, repair history, downtime, depreciation, lifespan.

6. Healthcare & Medical Procurement

- Why it matters: Equipment like MRI machines, surgical tools, and hospital beds need regular servicing, calibration, and consumables.

- TCO focus: Consumables, sterilization, breakdown risk, cost of failure, service contracts.

7. Public Sector & Government

- Why it matters: Public procurement needs to ensure value for taxpayers and often includes maintenance over decades (e.g., roads, schools, IT systems).

- TCO focus: Lifetime value, transparency, sustainability, cost predictability.

8. Education & Academia

- Why it matters: Budgets are limited and purchasing is infrequent, so assets like IT equipment and furniture must last long and be cost-effective over time.

- TCO focus: Training, support, replacement cycles, multi-year use.

9. Agriculture & Agribusiness

- Why it matters: Equipment like irrigation systems or tractors must withstand harsh environments and require service parts.

- TCO focus: Resilience, ease of maintenance, operating costs, yield optimization.

How Scale Operationalizes TCO in Procurement

We don’t just talk about value — we enable it:

1. RFx Templates with Cost Breakdown Fields

Structure bids to reveal long-term costs (support, warranty, licensing, training, etc.)

2. Weighted Evaluation Engine

Score bids on price, performance, and TCO components.

3. Supplier Insights & Risk History

Evaluate long-term cost implications based on past performance.

4. Transparent, All-In Pricing

No hidden charges or surprise add-ons — buyers know what they’re committing to.

5. Training & Integration Included

Scale delivers value from Day 1 with zero hidden onboarding costs.

Buy for Value, Not for Today

Choosing the cheapest option often costs you the most. TCO empowers procurement teams to see the full picture, avoid surprises, and make smarter sourcing decisions. With Scale, Total Cost of Ownership is not a buzzword — it’s baked into how you buy.

Ready to make procurement more strategic?

Book a Demo →